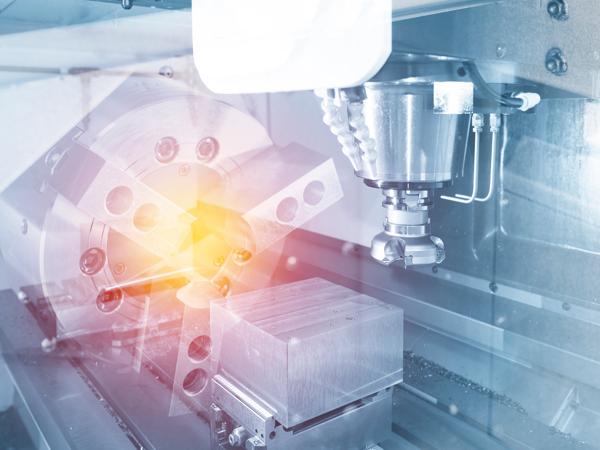

The world of metalworking is vast and varied, offering endless possibilities for creation and repair. Pneumatic power tools play a crucial role in this field, providing the precision and power needed to manipulate metals with finesse and efficiency. Let’s delve into the different applications where these tools make a significant difference.

Cutting Metal with Precision

Cutting is one of the fundamental operations in metalworking, and pneumatic tools provide a reliable solution for this task. Pneumatic shears, nibblers, and cutters are commonly used to slice through various metals. A pneumatic nibbler, for instance, is well-suited for making precise cuts in sheet metal without distorting the edges, which is crucial in applications like automotive body work.

Shaping and Forming

Bending and forming metal into specific shapes requires precision, and pneumatic tools are widely used in this application. Pneumatic hammers and presses are utilized to form metals through processes like embossing, flanging, or stamping. These tools are particularly handy in industries where precision metal parts are needed, such as in aeronautics or electronics manufacturing.

Surface Finishing for Smooth Results

Achieving a flawless surface finish is essential in metalworking, especially for aesthetic or functional purposes. Pneumatic grinders and sanders are popular choices for surface preparation and finishing. They are used to deburr sharp edges, smooth out weld seams, or polish surfaces to a shine. For more specialized applications, pneumatic polishing tools can be used to achieve a mirror finish on materials like stainless steel. For more information on using air tools for metalworking , see the comprehensive guide. The Fabricator offers insights on how pneumatic tools enhance the efficiency of these processes.

Joining Metal Pieces

Joining metal components is a crucial step in many manufacturing processes. Pneumatic rivet guns and welders provide the strength and efficiency required to secure metal pieces together. Riveting is a common practice in aerospace and construction industries. On the other hand, pneumatic welders are often favored in situations where traditional electric welders might pose a risk or are impractical due to environmental factors.

Maintenance and Repair Work

In the maintenance sector, pneumatic tools simplify the repair work by offering portable and durable solutions. Whether it’s about loosening rusty bolts or cutting through metal pipes, tools like impact wrenches and reciprocating saws prove incredibly useful. Their power and versatility help technicians and engineers accomplish repairs more efficiently and effectively. For more tips on keeping your pneumatic tools in top condition, see our guide on air tool maintenance tips.

Safety Considerations

While pneumatic tools offer numerous advantages in metalworking applications, safety is paramount. Always ensure the proper training is undertaken before operating these tools. It is also crucial to wear suitable personal protective equipment, including eye and ear protection, gloves, and steel-toed boots, to prevent accidents and injuries.

The use of pneumatic tools in metalworking applications represents just one aspect of their versatile nature. From cutting to finishing, the precision and power they offer are indispensable to craftsmen and hobbyists alike. Their reliability and efficiency continue to make them an essential asset in workshops around the world.