Pneumatic tools offer incredible power and efficiency for a range of tasks, from automotive work to carpentry. Essential to harnessing this power are the fittings and couplers that connect your air tools to the air compressor. Understanding these connectors can enhance your pneumatic tool experience by increasing efficiency and safety.

Understanding Fittings and Couplers

Fittings and couplers are the components that link your air hose to the tool and the compressor. They might seem small, but they are vital in facilitating a secure and efficient air supply. These components come in various types and sizes, each serving a specific purpose.

Types of Fittings

-

Quick-Connect Fittings & Couplers:

- These are designed for rapid attachment and detachment. They’re common in applications where tools are frequently changed. -

Threaded Fittings:

- These fittings screw onto the equipment and offer a more permanent connection. They’re suitable for tools that require a stable, high-pressure supply. -

Push-to-Connect Fittings:

- Easy to use, these allow you to simply insert the hose into the connector, making them suitable for quick setups and adjustments.

Materials Used

- Brass: Known for its resistance to corrosion and durability.

- Steel: Offers high strength but can be prone to rust without proper maintenance.

- Aluminum: Lightweight, making it easier to handle, though it may not be as durable as brass or steel.

Different Coupler Types

Couplers act as the intermediary between the hose and the tool, allowing for flexibility and ease of use.

- Automatic Couplers: Disengage by simply pulling on the coupler’s sleeve. Useful for quick tool changes.

- Manual Couplers: Require a bit more effort but offer a reliable connection for applications where air loss cannot be tolerated.

- Rotary Couplers: Allow the tool to rotate freely, reducing hose tangles and wear.

Sizing Matters

Fittings and couplers are available in standard sizes that correspond to the inner diameter of your hose. Common sizes include 1/4”, 3/8”, and 1/2”. Selecting the right size ensures maximum airflow and proper tool function.

Key Factors in Choosing Fittings and Couplers

- Compatibility: Ensure that your fittings and couplers match the specifications of your tools and air compressor.

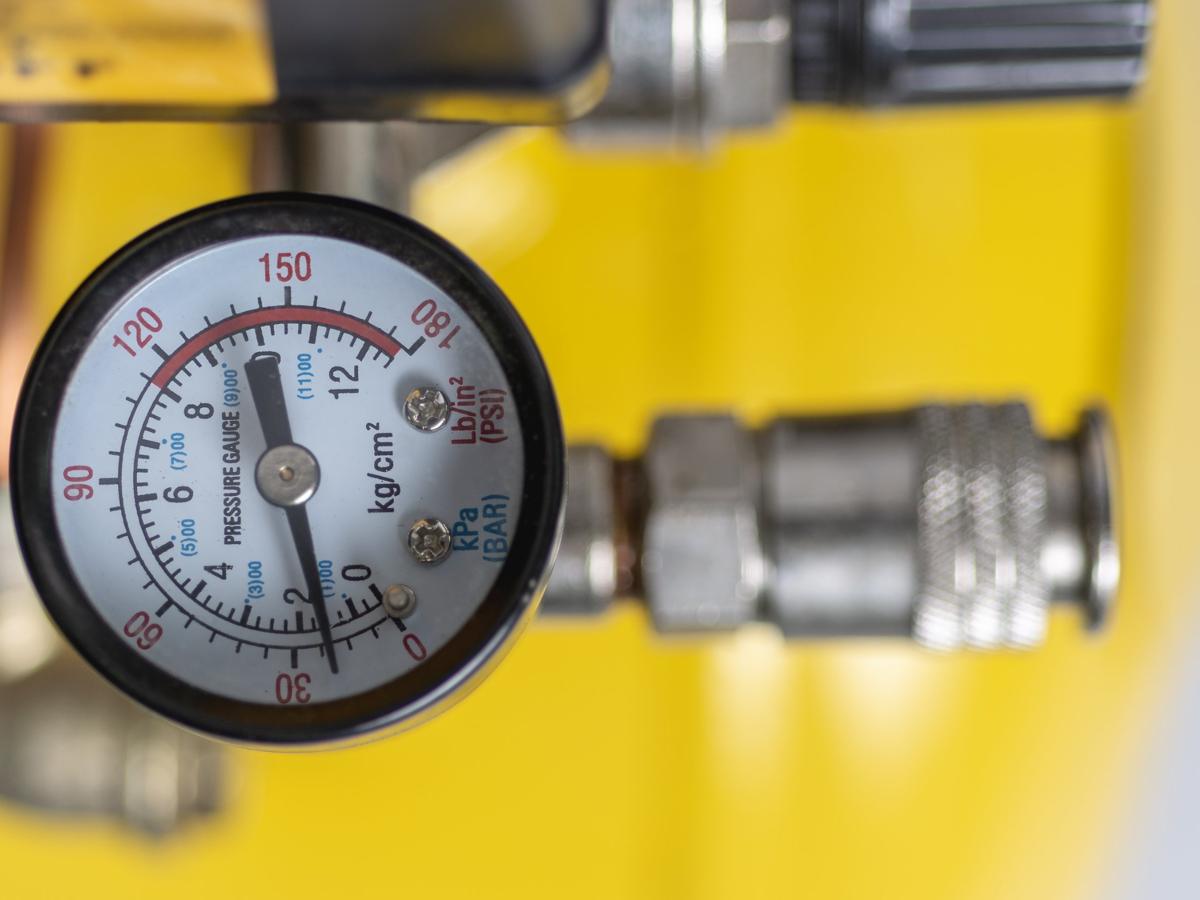

- Pressure Rating: Check that the components can handle the maximum air pressure you plan to use.

- Ease of Operation: Choose connectors that fit your working style, especially if frequent tool changes are necessary.

Maintenance Tips

Regular inspection and maintenance prolong the life of your fittings and couplers:

- Look for signs of wear and tear, such as cracks or leaks.

- Apply lubricant as recommended to keep the fittings functioning smoothly.

- Store the connectors properly to prevent damage from dust and moisture.

For more comprehensive guidance, check out this resource on air compressor fittings.

Understanding and selecting the right air fittings and couplers improves not just the effectiveness of your tools but also your overall satisfaction with projects requiring pneumatic power. Dive into each project with the confidence that your tools are securely and efficiently connected.