Selecting the right air compressor isn’t just about finding a machine to power your tools; it’s about understanding what matches your specific needs. With so many options, navigating the world of air compressors can feel a bit daunting. But worry not, we’ll walk you through the process with humility and camaraderie.

Understanding Air Compressor Types

Air compressors come in various types and each serves different purposes. Here’s a brief overview:

- Reciprocating Compressors: These are the most common, using pistons to compress air. They’re great for occasional and light use, like inflating tires or powering small tools.

- Rotary Screw Compressors: Best suited for industrial or continuous use, these are often found in manufacturing settings due to their efficiency. They are a type of stationary air compressor.

- Centrifugal Compressors: These are for heavy-duty industrial applications, delivering large volumes of air. They are less common for home or DIY usage but shine in high-demand environments.

Essential Considerations

When choosing an air compressor, take the time to consider the following factors:

Purpose and Usage

The first step is identifying what you’ll need the compressor for. If you’re only inflating sports equipment or using a few light-duty pneumatic tools now and then, a simple reciprocating compressor might suffice. However, for more robust or continuous usage, such as in a woodworking shop, a rotary screw compressor could be more appropriate.

Power Source Options

Air compressors can be powered by electricity, gasoline, or diesel. Most home and DIY users opt for electric compressors due to their convenience and availability. For remote sites without easy access to power, gasoline or diesel-powered compressors may be the solution.

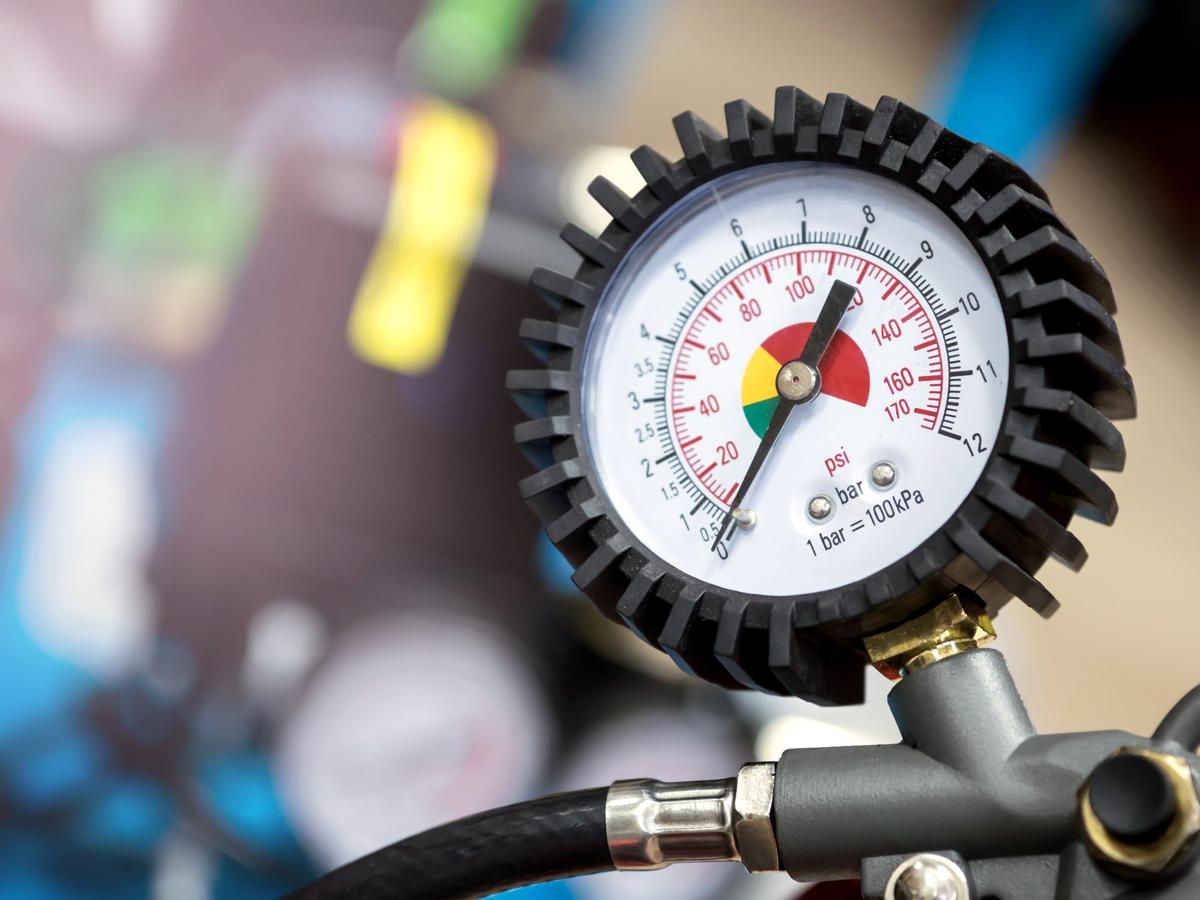

Air Pressure and Volume

The two critical metrics in air compressors are PSI (pounds per square inch) and CFM (cubic feet per minute). PSI refers to the air pressure, while CFM measures the volume of air delivered. Ensure your compressor meets or exceeds the PSI and CFM requirements of the tools you plan to use. For example, a framing nailer might require 2-4 CFM at 90 PSI, while a sandblaster might need significantly more. For help in selecting the right compressor, see our air compressor buying guide.

Tank Size

A larger tank allows you to run tools longer without the compressor needing to kick in as frequently. If your tasks involve constant air use, such as painting or sandblasting, a larger tank might be worthwhile. For quick tasks, a smaller tank may do the trick.

Portability

If you’re moving your air compressor around, portability becomes a factor. Smaller, portable air compressors are easier to transport but can be limited in capacity and power compared to stationary models.

Noise Levels

Air compressors can be noisy, with noise levels ranging significantly. If you’re working in a space where noise is a concern, consider a compressor described as “quiet” or “low-noise.”

Additional Features to Consider

Here are a few features that might add convenience or efficiency: You might find helpful How-To Tutorials to get started.

- Adjustable Air Pressure Regulator: Helps tailor the air compressor output to different tools.

- Quick-Connect Fittings: Make switching between tools quick and painless.

- Thermal Overload Protection: Prevents overheating, which extends compressor life.

Researching and Comparing Models

Once you’ve clarified your needs, research potential models. Look at manufacturer websites, read reviews, and compare specs. For unbiased evaluations, websites like Consumer Reports provide valuable insights into performance and reliability.

Budget and Cost Considerations

Finally, weigh the costs against your budget. While it’s tempting to go for cost-saving options, prioritize long-term value and reliability over initial price. Remember, the cheapest option isn’t always the most economical in the long run.

Hopefully, this guide equips you to find an air compressor that fits both your current needs and future aspirations. Whether you’re pursuing DIY projects at home or managing a bustling workshop, the right compressor can make your work smoother and more enjoyable.